Informazioni di Base.

colore

personalizzato

oem&odm

personalizzato

pacchetto

personalizzato

funzione

cottura

Pacchetto di Trasporto

Custom Packing

Specifiche

25x5x1.5

Marchio

Newtop

Origine

Fujian

Capacità di Produzione

5000000

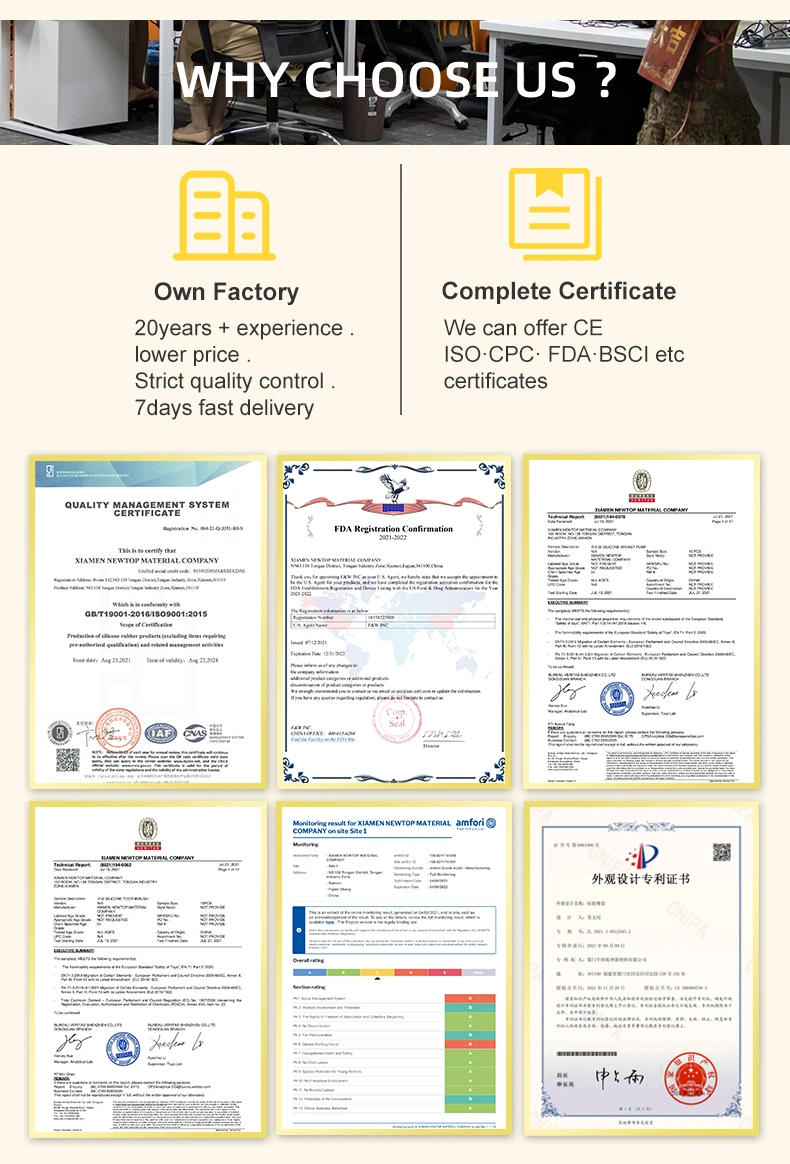

Descrizione del Prodotto

The 25x5x1.5" mold was designed for two purposes. First, as a mold used to create long and skinny boards for use as cheese or bread boards. Second, to be a coaster set mold, allowing the creation of (5) 5x5" coasters (or 4.5x4.5" or 4x4" coasters if you trim the long edges before slicing into coasters). We opted for the 5" width to allow it to be used for long cheeseboards, but also to allow for a margin of error when used as a wood and epoxy mold for coasters.

Crafted Elements Silicone Molds The last mold you will ever need. Created just for makers, resin artists and wood workers, these time saving flexible yet durable silicone molds significantly cut down on the setup and demolding time usually involved with other molds. Silicone molds are superior to wood and tuck tape, and HDPE molds because: They can be used with epoxy resin, resin and wood, concrete, Jesmonite, plaster and more. They never need assembled, or disassembled. Saving huge amounts of time. The corners and edges never need sealed.

Crafted Elements Silicone Molds The last mold you will ever need. Created just for makers, resin artists and wood workers, these time saving flexible yet durable silicone molds significantly cut down on the setup and demolding time usually involved with other molds. Silicone molds are superior to wood and tuck tape, and HDPE molds because: They can be used with epoxy resin, resin and wood, concrete, Jesmonite, plaster and more. They never need assembled, or disassembled. Saving huge amounts of time. The corners and edges never need sealed.

The mold is heat resistant to ~450F. Avoid direct contact with the flame of a torch.

Cooking spray, vaseline, silicone based sprays or sprays designed for urethane or polyester products should NEVER be used. Using a proper, non-silicone based mold release can mean the difference between getting only a couple of uses from your mold to 20, 30 or more.