Informazioni di Base.

colore

personalizzato

oem&odm

personalizzato

pacchetto

personalizzato

funzione

cottura

Pacchetto di Trasporto

Custom Packing

Specifiche

24x8.5x1.5

Marchio

Newtop

Origine

Fujian

Capacità di Produzione

5000000

Descrizione del Prodotto

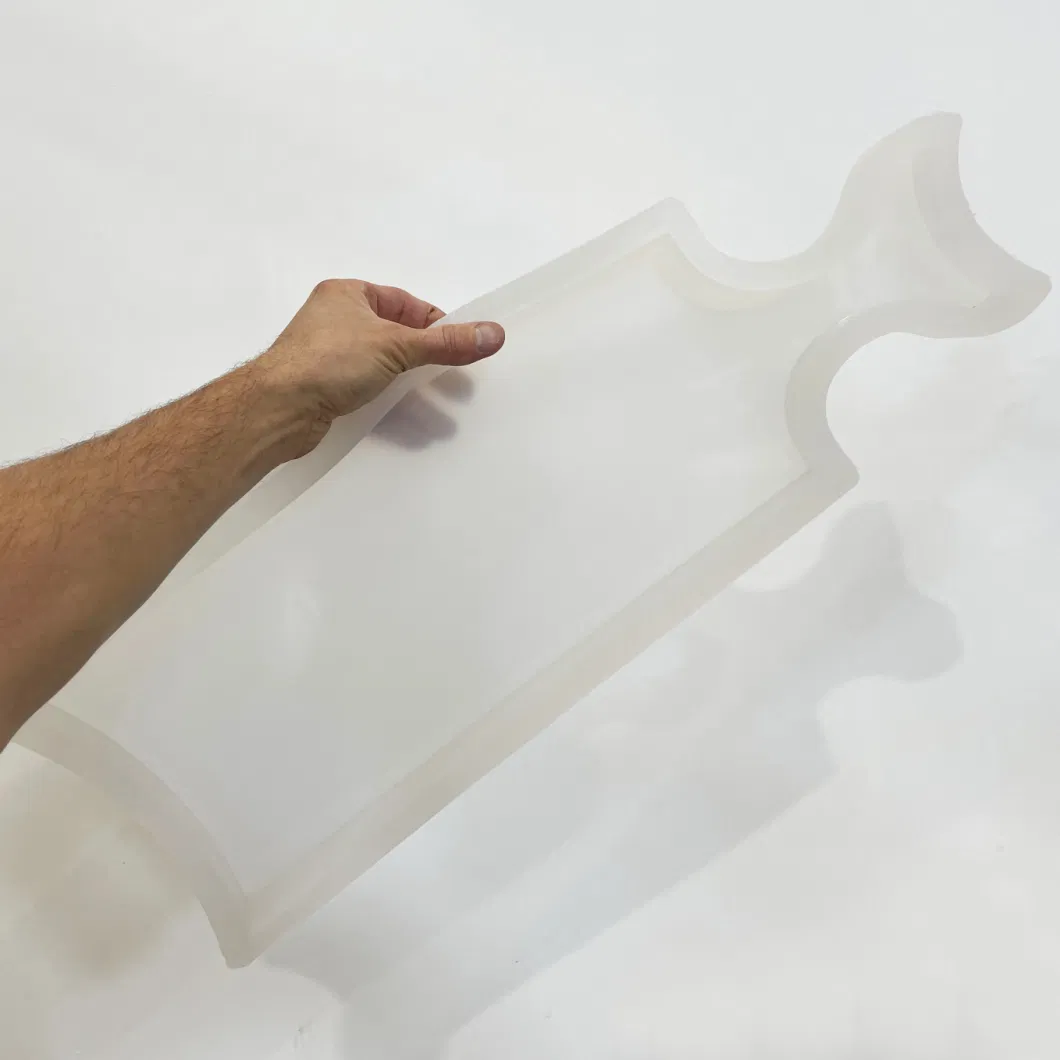

The integrated handle shape makes creating high quality resin (or resin and wood) serving boards a breeze. No more cutting, forming, and routering handles after the fact and wasting material. You can now create solid resin handles right at the time of your pour. At nearly 1.5" in depth, you can use this mold to create mixed media boards with wood and resin, or just pour up to 3/4" in height to make a thinner full-resin board.

This particular serving board mold features a flared body that is 8.5" wide at the base and a fish tail like handle. The size of the finished charcuterie board without the handle is 17.75"x8.5", with the handle included, the finished piece is 24" x 8.5", at up to 1 3/8" in depth (depending on the volume of your pour).

Crafted Elements Silicone Molds The last mold you will ever need. Created just for makers, resin artists and wood workers, these time saving flexible yet durable silicone molds significantly cut down on the setup and demolding time usually involved with other molds. Silicone molds are superior to wood and tuck tape, and HDPE molds because: They can be used with epoxy resin, resin and wood, concrete, Jesmonite, plaster and more. They never need assembled, or disassembled. Saving huge amounts of time. The corners and edges never need sealed.

This particular serving board mold features a flared body that is 8.5" wide at the base and a fish tail like handle. The size of the finished charcuterie board without the handle is 17.75"x8.5", with the handle included, the finished piece is 24" x 8.5", at up to 1 3/8" in depth (depending on the volume of your pour).

Crafted Elements Silicone Molds The last mold you will ever need. Created just for makers, resin artists and wood workers, these time saving flexible yet durable silicone molds significantly cut down on the setup and demolding time usually involved with other molds. Silicone molds are superior to wood and tuck tape, and HDPE molds because: They can be used with epoxy resin, resin and wood, concrete, Jesmonite, plaster and more. They never need assembled, or disassembled. Saving huge amounts of time. The corners and edges never need sealed.